1891 Charles Walker's Early Riser's Friend

The first known teasmade was invented by Charles Maynard Walker. It predates Rowbottom’s invention by a matter of months. Details of Walker’s teasmade were published in Work Magazine (No 131) on September 19th 1891, complete with illustrations, but alas, I believe it was not patented. The article is very detailed and is reproduced in full here:

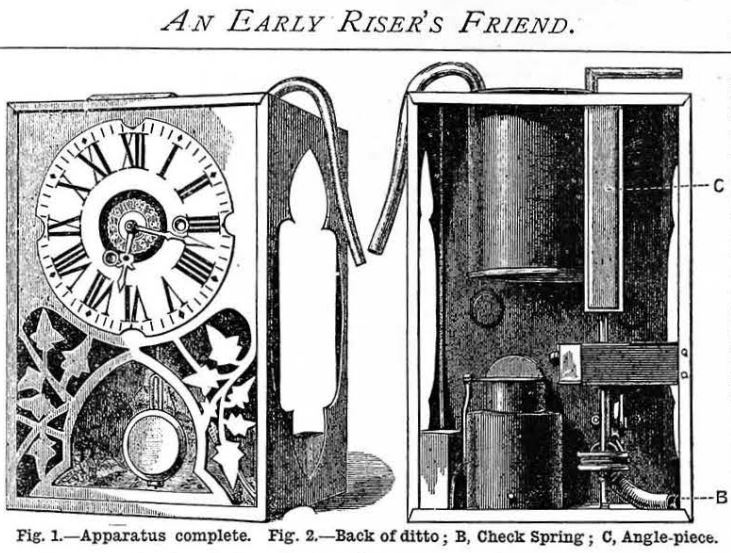

How to make an alarum for early risers, which will strike a match, light a lamp, boil water, make tea or coffee, and awaken the sleeper at any required hour. The advantages to be derived from the habit of early rising, whether viewed from the points of obtaining or retaining health, or for the lesser objects of acquiring wealth by devoting more hours to labour, or of riding some particular hobby, are pretty generally admitted; and while it may he true that most persons living in the country practise from choice the laudable habit with a regularity that is perhaps hereditary, and also that thousands are compelled to rise early in order to follow their employment, whether they like it or not, it is equally true that a very respectable minority, who, while recognising the advantages of early rising, fail to acquire the habit, either from a want of strength of purpose from natural sleepiness, or from some other reason equally powerful to keep them in bed, and who therefore usually “oversleep” themselves – unlike the late Duke of Wellington (the Iron Duke), who is reported to have uttered and acted upon the statement that “when a man turned over, it was time to turn out.” The enormous trade in alarum clocks, carried on in this and other countries, is evidence that the class of persons referred to is a very large one; and as, doubtless, many of them are readers of this Magazine, and therefore anxious to carry out some of the excellent suggestions therein, will welcome the instructions here given, which, if carefully carried out, will put them in possession of a faithful servant, which will minister to their comfort by calling them at any desired hour, and, further, getting the breakfast ready at the same time. In these instructions it is to be understood that the parts are of such form and of such material as are best suited to be made up by persons capable of doing ordinary soldering with sheet metal, and without the use of expensive tools; therefore, such parts of the apparatus which could be much better made from castings and turned may be with advantage so altered. However that may be, the present plan will answer every purpose. Fig 1 represents the complete apparatus, the dimensions being: height 8 inches, width 5 1/2 inches, depth 5 1/2 inches externally, and is taken from a photograph of one in use, made by the writer. The outer part or case case is made of tin plate. The internal fittings are of wire and tin of the simplest kind, so that anyone capable of “jobbing” tin work may undertake the work with every probability of success. The clock part is an ordinary alarum clock, known in the trade as a “Cottage Alarm,” and can be bought through any clock dealer, or direct from Messrs Meyer, Aldersgate Street, EC, for about 3s 6d. This will be found a serviceable article. When purchased, it will be in a wooden case, which will of course be dispensed with and put to some other use.

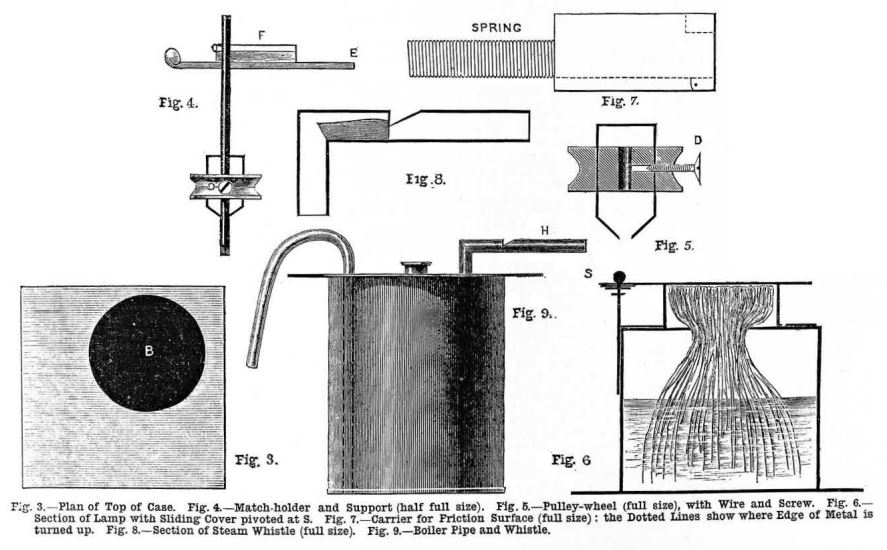

We shall first require to make up the case (Fig 3), which will need but little explanation beyond pointing out that the edges of the front are turned over on three sides only, the bottom being left to admit of the front sliding into its position; also that the device or cut out at the sides is simply to combine a little ornamentation while strengthening the side. The cutting should be made before the case is made up ; also the hole, B, 3 inches in diameter, should be cut. The case is quite open at the back, and from the front a kind of inner case extends 2 and an eighth inches inside of tin which will presently form the case proper of the clockwork. In the back of this inner case, at a point 1 1/8 inches from the bottom and l inch from left hand side, is cut an oblong hole, 1 1/8 inches deep by 3/8 inch wide. This case should be very neatly made and its sides true to each other, or the finished work will present an awkward appearance. We have now to fit up the mechanism, and it will be best perhaps that, at this point, a description of the general idea should be given. We have an alarm clock, which, in its present form, simply sounds a bell at a given hour. We want to make the clock carry out our purpose, so that, in addition to being awakened, we shall be provided with tea or coffee, ready to hand when the alarm is given. In order to do this, we remove the spring of the alarm, and in its place attach a piece of catgut. Connect this to a piece of mechanism at the back of the case, which will carry and strike a match in such a position that the match will ignite a spirit lamp under a small boiler, the water of which will run out as soon as it boils into a tea or coffee pot, and at the same moment sound a shrill call with a whistle on the boiler. The writer has endeavoured to arrange the parts so that they occupy a comparatively small space, and that the case shall present a fairly ornamental appearance, the front (Fig 1) being a design cut out of zinc with the fret-saw, and the dial of clock let in behind, the whole sliding up the groove referred to in case (Fig 3).

The details of the various actions of the interior will now be described. Having made the outer case, we require to make the necessary alteration in the clock. Remove it from the case, and take out the wire holdfast on the alarm side, so as to be able to raise the plate. You can then, with a little care, take out the spring-wheel and spring, cutting the latter clear of the bar to which it is fastened to the clock. Having removed the spring from the wheel, punch out the rivet which held it in its place, and in lieu thereof pass one end of a length of catgut (14 inches) through the hole. Leave about half an inch of the catgut out, tie a small knot, and restore the wheel to its position in the clock, and fasten up the plate as before. In front of the spring-wheel, at the winding-up pin, will be noticed a peculiar shaped piece of brass, which acts as a stop to the winder, and prevents the work being overwound. We shall require to readjust this later on. Further down at the bottom of the works will be noticed an escapement in connection with the alarm, having a small weight on a piece of wire, which acts as a bell-hammer. Cut this off with wire-cutting pliers. Also notice attached to this two steel pellets, which, when the alarm runs down, alternately escape, and give the necessary intermittent action of striking the bell. We do not require an intermittent action, but a continuous run down. So take firm hold of the lower pellet, and break it off. Being hard steel, it will readily snap. Hold the other part firmly, so as not to break both off. Now set the clock aside for a time. Then make a bearing to connect the catgut at right angles, for which purpose we require a pulley-wheel (such as are used by venetian blind makers, and sold in London about sixpence per dozen). This is fitted in

the slot in the back of case by passing a piece of wire through the wheel, and soldering to the case. As this has to bear a considerable strain, the ends of the wire should be bent over, and let into the case before soldering. This will ensure the necessary strength.

We now require to make the match-holder and axle (Fig 4), which consists of an upright piece of wire, 1/8 inch thick by 4 1/8 inches long, to which, at a point 1 inch from bottom, is fitted another pulley-wheel, of the same kind just described. This is readily fastened by first drilling a hole on each side of the centre, passing a piece of bent wire through, as shown in Fig 5, and soldering to the upright. Bore another small hole, and insert a screw, D. This will later on be connected to the catgut. At the upper end of Fig 4 will be seen the match-holder, which is simply a piece of tin or zinc, 1 inch long by 1 inch wide, bent over a piece of 1/8 inch wire, and pinched in under the wire, leaving a kind of tube when the wire is withdrawn. This is soldered to the upright, 1 inch from the top, and at right angles to the screw, D. A piece of tinned or brass wire is bent, as E, with an eye 5/8 inch from the holder, F, leaving 1 3/4 inches extending in the opposite direction. This is soldered to the holder and to the upright, neat and strong. The next operation is to provide bearings for this work. The lower one will consist of the bottom of the case. For the upper one we must make an angle-piece (C, Fig 2) – a piece of stout brass or zinc, 3/4 inch wide, 7 1/4 inches long, bent to a right angle, 4 inches by 3 inches, and soldered, the longer end to top of case, the shorter end to back of case, at a point 1 1/4 inches from the right-hand outside of case. Before soldering up, however, a hole to admit the upright should be punched in the shorter piece, at a point 1 1/4 inches from the bend. Having soldered this up, make a corresponding hole in the bottom of case, exactly under the other, so that the match-holder action-work will be vertical – that is, as shown in Fig 4. If the measurements have been correctly made, you should have about 1/8 inch to spare of the upright wire at each hole, and you can now secure this into its place, so that while it is free to move round, it cannot move up or down, by soldering at each end a bead of solder slightly larger than the holes.

We now require a small spirit lamp (Fig 6) which is easily made of sheet zinc. The lamp is circular, with a square base, 1 3/4 inches high to shoulder, the part which forms the burner extending 1/2 inch higher, having a diameter of 1 1/4 inches. A “hank” of ordinary white darning cotton cut into three and placed inside the lamp forms a capital wick. The latter should not project above the lamp when in use, or it will hinder the action of the slide-cover. This cover is connected with an upright wire soldered to side of lamp (Fig 6), and at a point level with top of lamp. A ledge is soldered to the wire. A hole is made in the extended side of cover, and is passed over the wire. A bead of solder on top serves to secure it, while leaving it free to move. Across the cover is soldered a semicircular piece of tin, against which the wire at the apposite end of match strikes and knocks it away.

We have now to make the holder for the striking surface (Fig 7), which is given full size, and is simply a piece of tin with edge and corner turned over at dotted lines. This is attached to a piece of crinoline steel spring,

and soldered at its other end to the right-hand upright of case. It is best before soldering to pierce the steel, and insert a portion of an ordinary pin – the head part, and as much as is wanted of the stem. The steel must be softened at the ends to enable this to be done, which is readily effected by holding the ends in a lamp-flame till slightly red, and letting it cool of itself. It can then be punched with the point of a centre-punch or bradawl. The spring, when in position, should be curved inwards, so that the eye of match-holder just clears it. Thus, when the projecting match is in the holder, it will strike with some force. I prefer to use safety matches – the large size, Bryant and May’s – and in the striker I place a piece of their friction surfaces, which are sold at most Italian warehouses at twopence per packet. Each sheet cuts into three, and each of the three is used four times – that is, I turn a different corner to the path of the match each time. Thus, a twopenny packet will last about nine months, daily use. I keep the box of matches in the case at the left-hand of lamp, and solder a strip of tin upright, which serves as a holder for the matchbox, and keeps the lamp in position. The latter is best made with a

square bottom, and to fit easily into the space left of the floor of the case. The lamp, of course, should be under the hole in top of case which was provided for the boiler (Fig 9), which is 4 inches deep by 3 inches wide. The top extends 3/8th inch beyond, all round. A piece of compo pipe, 1/4 inch bore, is soldered into top, near edge, and reaches to nearly the bottom; or, what is better, cut the pipe on the “skew”, so that the water can run easily. A brass screw-cap is used for the filling hole, and a brass whistle (H) is made in an elbow form. Take a piece of brass tube, 1/4 inch bore, 2 3/4 inches long. Saw off 3/4 inch, so as to make a mitre, and on the longer piece, 3/4 inch from mitre, file an angular cut (Fig 8). Stop up the longer end with solder, and insert in the shorter end a piece of cane or hard wood, the exact size of the tube, having previously filed the top flat, about 1/16 inch, slightly more at the mitred end. Just try it, and if you like the tone, secure the wood in its place by drilling a very small hole, and pass a pin in and solder to tube. Now solder the shorter end to top of the boiler, having previously made a hole at the spot. Next take a piece of suitable ordinary “bell-check” steel spring. Fasten the loop end to a piece of wire, and having passed the wire through the base of clock case, at the right-hand corner extreme point, solder underneath, and bend the other end of spring wire over the screw, D, in Fig 5, so that when at rest it pulls over the striker a little beyond its proper position of being over centre of lamp.

There remains now only to fix clock movement into position, and connect the catgut (through the opening of clock case back) with the striking work at the point D. This is easily done by giving the gut a turn over D, and tying it to the wire over wheel. The gut should be so fixed that it brings back the striker to its position to centre of lamp. It will he necessary, of course, to pass the gut round the wheel, and the point D should be in the position of right angles to the striker. Now, if you wind up the alarm, you will see the action of the brass stop, before referred to. Take it off and adjust it when you have wound the gut up far enough to bring the striker to the right-hand side of case, so as to be easily manipulated in fixing match, and taking out the same. Stop its further turning by putting the stop so that it can turn no further. Replace the pin. Try the work a few times, seeing that the alarm escapement frees itself readily, and the work runs down with a sudden run. This being found all right, paint the whole (except clock) with black japan, and, when dry, slide into position the clock face. Fix on the hands and pendulum, and all is ready for use. I find about half a pint of spirit is used in a fortnight. As spirit easily evaporates, the cover must be put back as soon as lamp is blown out. Do not put the match in holder until

wound up. I use a small china tea-pot, set under the pipe of boiler, for tea, and a jug for coffee. The apparatus makes these or cocoa admirably, from the fact that the water is actually boiling over when it comes into contact with either.

With thanks to “The Work Magazine Reprint Project” www.toolsforworkingwood.com from whose scanned copies this article was transcribed.